The perfect crate

Analysis of requirements

- Type of packaging required: primary, secondary or tertiary packaging

- Single or combined functions: containing goods, protection, information

- Dimensions, weight, type of object and material

- Handling and storage modes and means of transport.

TYPES OF RISKS

- PHYSICAL: such as falls, shocks, lifting, slinging, compression, bending, rolling and vibration;

- CLIMATE: such as water, humidity, heat, solar radiation, frost, oxidation, air pollution and pressure changes;

- BIOLOGICAL: such as infestations and bacteria.

CHEAPEST PRICE CONSIDERING:

- the materials used;

- production processes;

- any damage to the transported goods;

- handling, storage and transport;

- packaging recovery/recycling.

Our aim is to ensure that the goods to be delivered to the customer are well protected

product lines

Protective packaging

Packaging is meant to protect products to avoid breakage and deterioration due to handling, transport and weather conditions. If such protection is partial or ineffective, the user/customer is likely to make complaints, return the goods and request new shipments. Therefore, unsuitable packaging leads to substantial economic losses that can be avoided.

Specific packaging requirements are the main focus of our customised service, which includes delivery and after-sales.

Design and implementation process:

- Gathering technical requirements

- Studying the life cycle of packaging

- Design: optimising space, materials and the production process

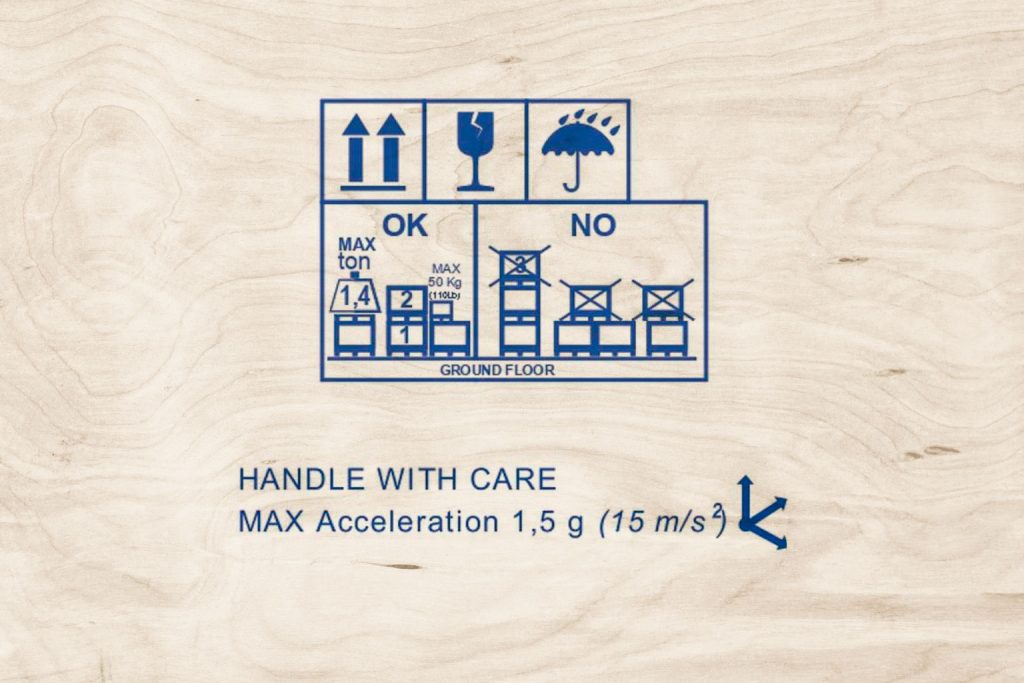

- Printing useful product information: insertable weight, stacking quantity and method, where to fork or tie, where to open, disposal, etc.

Scalable levels of customisation for standard and custom crates

- Packaging designer: customised packaging design

- Logo and text printing: once packaging is produced, the customer’s trademarks and graphics can be printed on it.

- Slide frames and supports for housing materials: stabilisation of goods

- Handles/closures that make it easier to handle the packaging and improve its safety

When designing your packaging, we can advise you and help you determine what your packaging needs are and prepare the relevant data sheet to ensure goods are shipped and stored as safely as possible.

Less waste and costs for you

For many years now, we have been offering the Just in Time service, which allows you, our customers, to benefit from multiple advantages through optimised management, which translates into less waste and lower costs:

- reduced storage costs: we produce only the necessary amount, which means less goods are handled and kept in stock

- reduced risk of obsolescence or that products will not be used. By working with minimum stock levels, products are less likely to become obsolescent

- Increased ability to respond to market fluctuations.

CAPACITY TESTS

5 or 7 laboratory tests

Packaging is meant to protect products from many risks that can be simulated in the laboratory in order to test the capacity of the product and, therefore, its validity. These tests include drop and impact, static and dynamic compression, vibration with or without load, and different weather conditions. Our company philosophy is based on supplying quality products and services, which is why all of our standard crates undergo the five tests listed here.

- Vertical drop test

- Constant load or static compression test

- Dynamic compression test

- Horizontal impact test

- Tilt tests

- Conditioning tests at controlled temperatures and humidity

- Conditioning tests at temperatures < 0